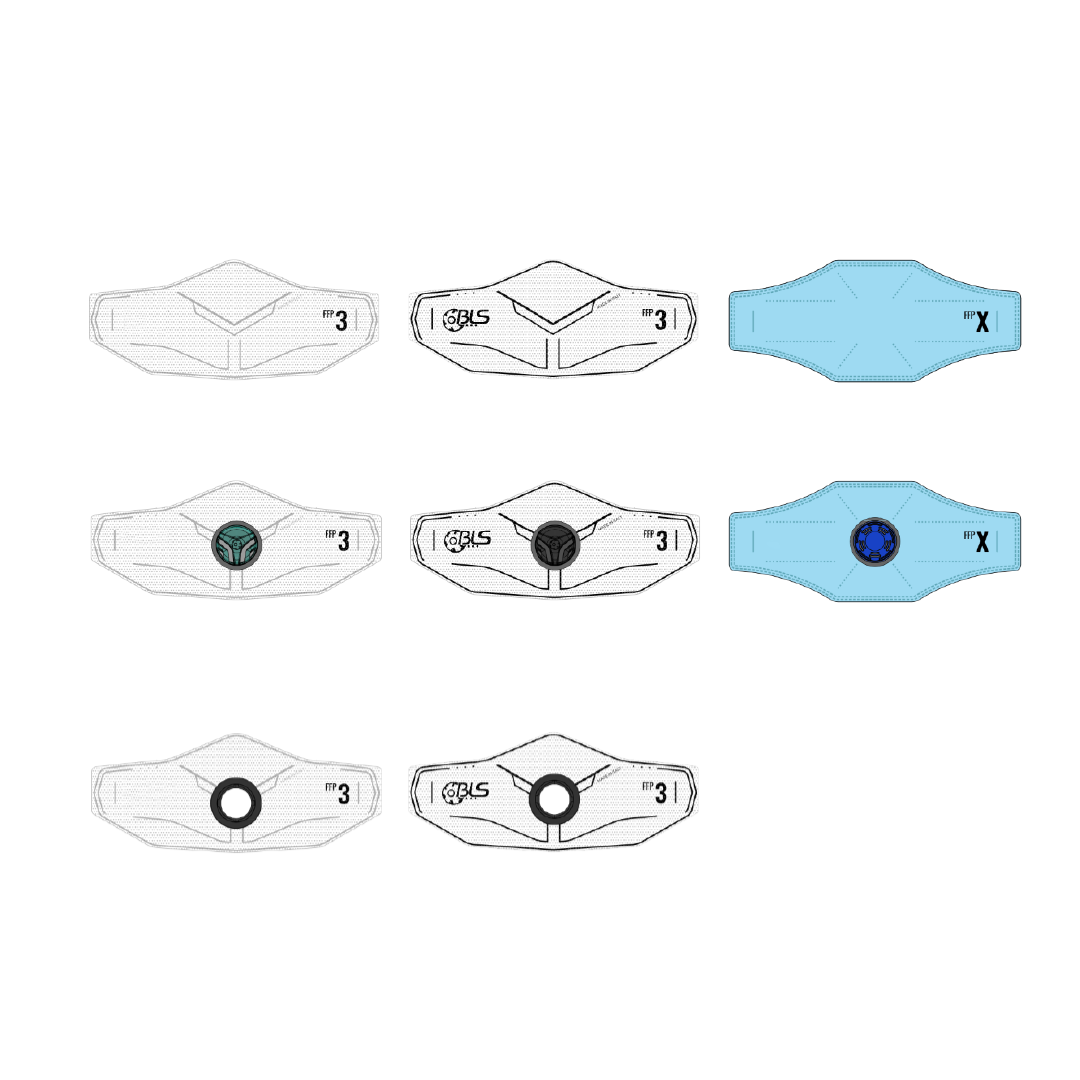

FFP3 Mask BLS Zer033 Flat Series

Product Design and manufacture of the disposable three-flap filtering facepiece for industrial use, for protection against dust and odors.

0. NDF Impact

1. PRODUCT DEVELOPMENT BRIEF

Customer BLS Group decides it wants to replace two of its products with a new, higher-performance disposable mask by adopting a new production technology. The new product is to be designed and manufactured from scratch based on the new production line, identifying differentiating selling points from competitors.

2. DESIGN CHALLENGES

Project challenges are located on various levels of design.

Differentiation

Aesthetic, functional and market differentiation from competitors

Production and technological constraints

Increased product performance was not to affect that of the production process in any way

Double size

Management of a double size in the production line without impacting investment

3. DESIGN PROCESS

Scanning the project into its most relevant design stages.

Product Development Research

The process began with a cross-user analysis together with the client. User journeys, related needs and design insights were defined. This analysis, together with a competitive study and analysis of market feedback from past years, led to an optimization of the client’s brief.

Concept development

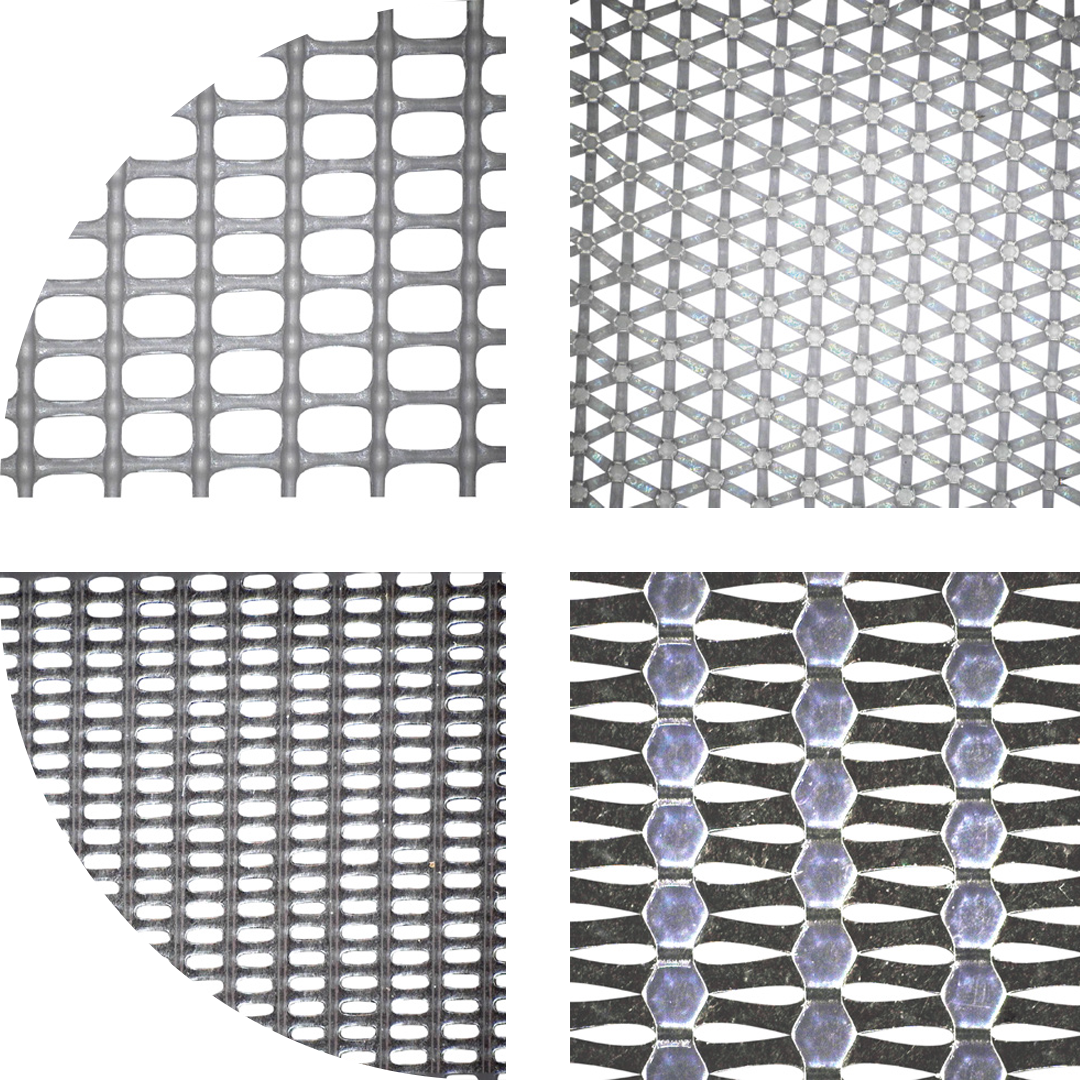

The concept had to take into consideration the production constraints of the production line. a “big” job was done to find characterizing shapes and innovative materials.

After an initial design phase, an internal realization of a POC was made to show to the client.

Then the first tests were carried out through the prototype and iterative cycles of improvements and revision.

Product Engineering

At this stage, the best materials that would ensure high performance on the product and high machinability on the production line were tested and defined.

The project was concluded with the delivery to the customer of all the technical documentation required for the production line.

Production

Cycles of changes and optimization of materials occurred as the project progressed to adapt to the technological choices implemented on the line, ensuring flexibility and total absence of lock-in in design choices.

4. PROJECT OUTPUTS

From the breakdown of the initial problems, some design solutions were proposed that were able to convert technical limitations into a structural renewal of the starting product

New system to be patented

Through the limitations of the material to be adopted and new technologies capable of manipulating it, the design effort resulted in a novel solution for the client.

The new structural system to be included in the filter met all technical requirements, improving compatibility between production costs and manufacturing processes.

Continuous Iterations

Despite the limitations of the materials that could be used and the new technologies capable of processing them, the design effort resulted in a novel solution for the customer.

Gallery

Whatever your project challenge, we respond with innovation and concrete solutions to support and guide you in your advancement and growth process, in line with your objectives.