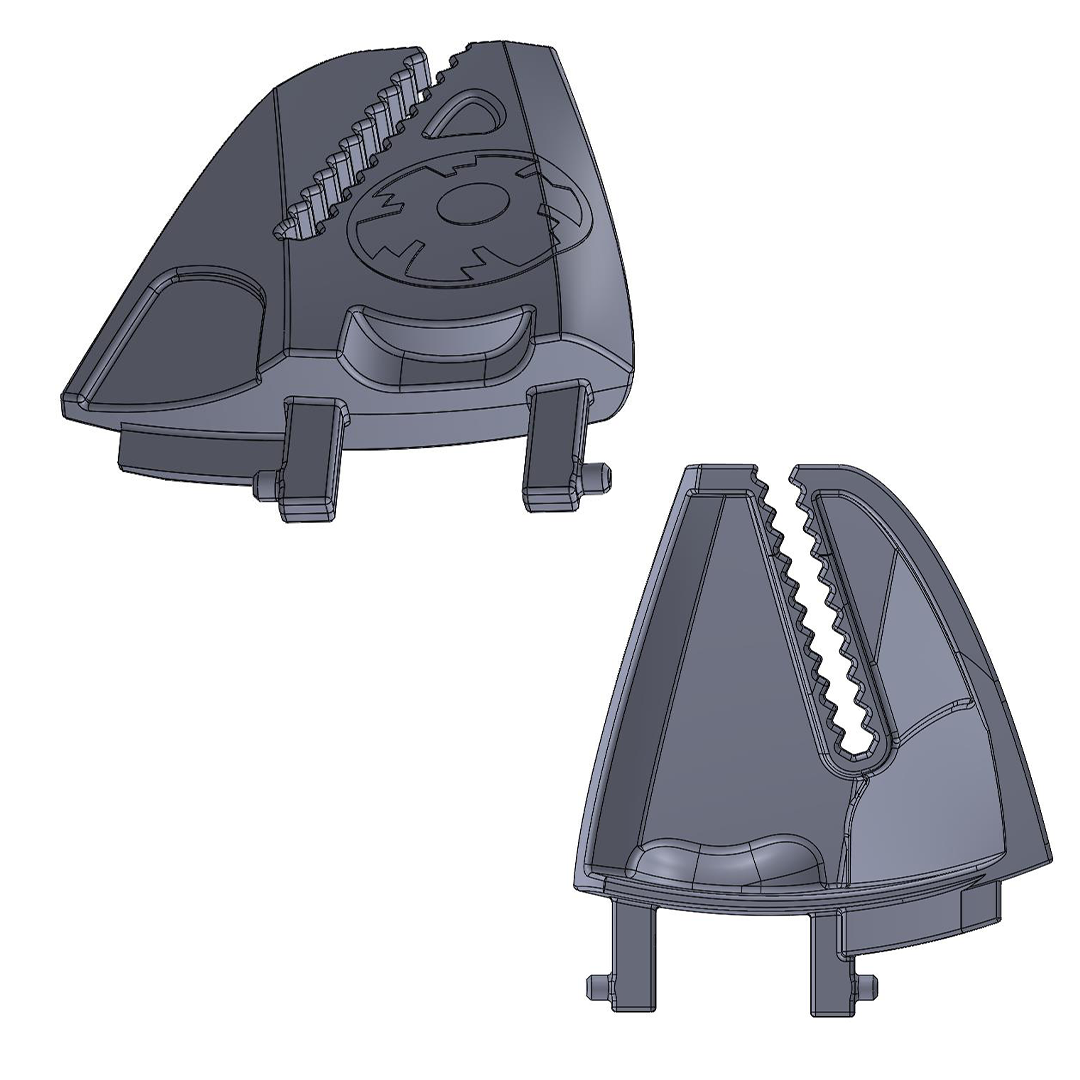

C-22 Lens Frame

Certifications

CE 0426

EN 140:2000

Corrective lens frame for full face mask for industrial use.

0. NDF Impact

1. PRODUCT DEVELOPMENT BRIEF

The project stems from the need to replace the current frame in use on BLS 5000 series full face masks with a more modern, stable and ergonomic product

2. DESIGN CHALLENGES

As already highlighted in the client’s brief, the product design challenges are located on various levels of the design.

Economic constraints

Due to the low sales volumes of this accessory, investment on the molds had to be low.

Aesthetic consistency

Starting from an existing frame, the new components had to dialogue both functionally and aesthetically.

Adaptability

The new frame had to fit the company’s 3 full face mask sizes.

3. DESIGN PROCESS

Scanning the project into its most relevant design phases.

Product Development Research

The process began with a cross-sectional user analysis together with the client. User journeys, related needs and design insights were defined. This analysis, together with a competitive study and analysis of market feedback from past years, led to an optimization of the client’s brief.

Concept Development

The concept had to take into account the constraints of the selected frame and began with reverse engineering work in order to best fit the new temples. After an initial design phase, a POC was created in-house to be shown to the client. Then the first tests were carried out through the prototype and iterative cycles of improvements and revision.

Industrial Product Engineering

The final phase involved the engineering of the individual components. Technical details for injection molding, such as draft angles and position of the ejectors, and aesthetic details for photoetching the molds were defined, dialoguing with various suppliers

The project was concluded with the delivery to the customer of all the technical documentation required to put the product into production.

4. PROJECT OUTPUTS

From the breakdown of the initial problems, some design solutions were proposed that were able to convert technical limitations into a structural renewal of the starting product

Low investment, maximum result

By making a single mold with two impressions, both temples were made and adapted to an existing frame

Flexible stability

An attachment system allows the frame to provide stability while adapting to the customer’s face and following different physiognomies

Gallery

Whatever your project challenge, we respond with innovation and concrete solutions to support and guide you in your advancement and growth process, in line with your objectives.